Tekna is proud to support the Prevention Day dedicated to the fight against breast cancer, which will take place on Sund

Our sectors

In today’s competitive world it is essential that production companies are dynamic, innovative and that they continuously monitor their production processes. The experience gained by Tekna in the industrial automation of machines and production lines, in robotized systems and vision systems allows it to provide Automation solutions aimed at optimizing production processes in various sectors and to provide integrated compliant supervision solutions. to the criteria of Industry 4.0.

The Automotive represents the historical field of application of industrial automation. Thanks to its experience and expertise accumulated in the sector, Tekna Automazione e Controllo is able to offer solutions for the construction of industrial automation systems for production lines, developing applications according to the specific needs of the customer.

The application of automation and new generation power systems allow to optimize and speed up the unloading and handling phases of materials in ports, whether they are bulk products, coal or containers. The experience gained in the safety of machines (suspended loads), in speed regulation (DC and AC motors), in the application of decentralized intelligence (P.L.C. and remote units), in supervision (on board the machine and on the ground with connection Wireless), allow Tekna Automation and Control to provide end customers, port authorities, shipyards and machine builders with integrated solutions for the Automation and Revamping of port crane machines.

The production of flat glass and curved glass in the automotive and civil sectors requires automatic systems of high precision and speed to guarantee reduced cycle times and the minimum required tolerances. The applications developed by Tekna Automation and Control for the automation of machines and lines for the production of side windows, windscreens and rear windows, as well as for the bending and tempering of glass, have allowed it to acquire specific know-how in the automation of glass processing processes that make Tekna an ideal partner for the development of glass production lines and tempering ovens.

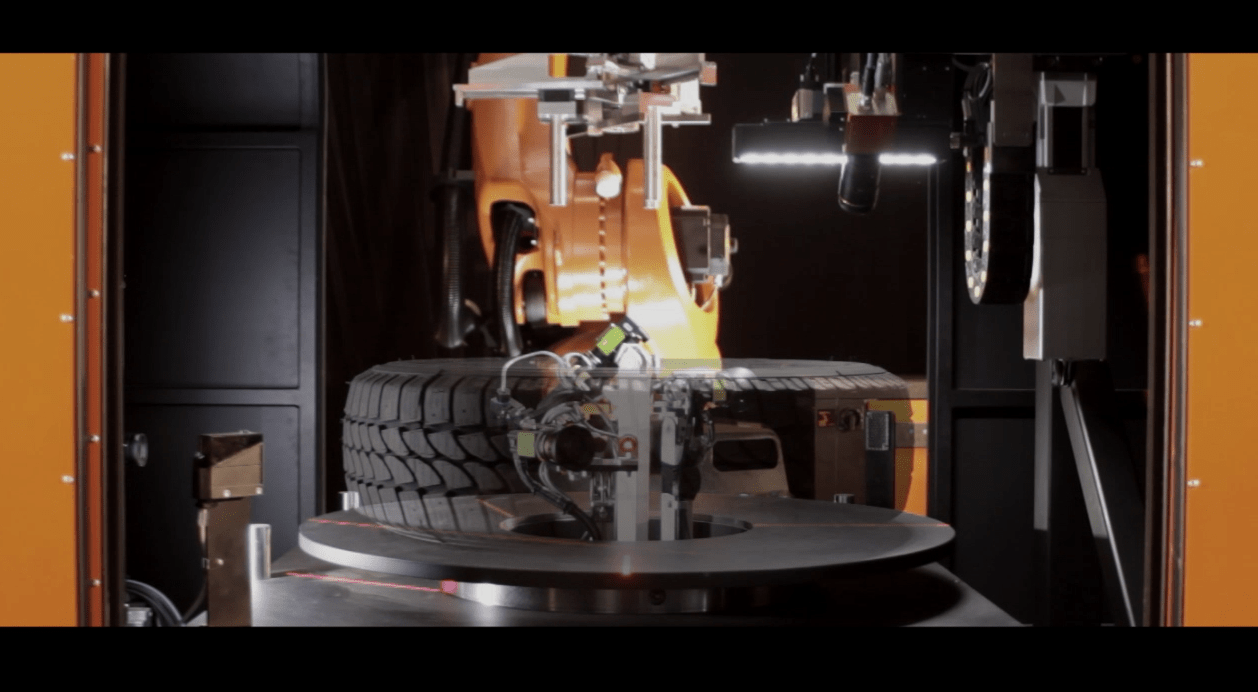

Tire production requires the automation of high power variable speed systems, extruders and calenders, as well as the careful and precise synchronization of handling systems, conveyors, winders and unwinders, to guarantee the required thicknesses and avoid accumulation and material ironing. Tekna Automazione e Controllo is able to offer automated applications at any stage of the production process for the production of tires and systems for quality control of semi-finished and finished products.

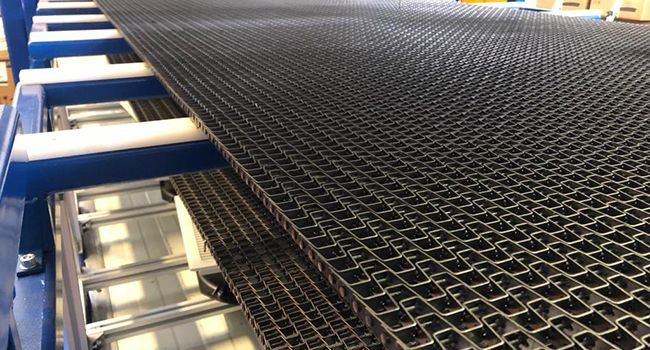

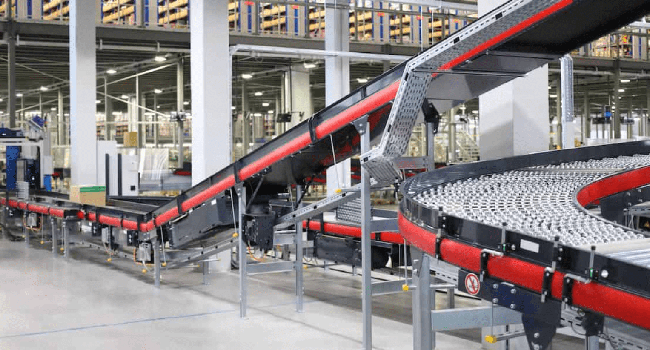

Tekna Automation and Control designs and manufactures industrial transport systems for the automated handling of goods and materials in production plants. Industrial transport systems designed for moving loads, raw materials, pallets and products within the production circuit guarantee efficiency, optimization and increased productivity.

An efficient and modern machinery is the necessary condition to increase the yield and productivity of the production lines. Revamping indicates a restructuring and reconstruction of industrial production lines in order to extend their life cycle. The obsolescence of Automation components, the unavailability of spare parts and the need to increase productivity are the primary elements that suggest the replacement of obsolete but perfectly functioning production lines. Unfortunately, the purchase of new lines requires huge investments, not always financially available on the part of the production company. The Revamping of the production lines, and their updating with new technologically advanced Automation systems, is the low cost solution to guarantee the continuity of production with a reduced investment.

More and more food companies are using automation systems for their production lines, regardless of size. Applied to food production lines, automation makes it possible to obtain products with a higher quality, to optimize product picking, positioning and processing times and to speed up packaging operations, as well as the formation of pallets.

They consist of technological systems and tools that are designed to make the processes of storage, picking, loading and unloading of goods completely automated. Tekna Automation and Control offers solutions in the design, construction and integration of automated logistic systems that act in total autonomy. In automated warehouses, the whole process of moving goods takes place more quickly, with a robotic intervention that allows the operator to pick up quickly with an increase in productivity. Logistics is becoming increasingly smart and managed through the human worker who will be an integral part of the system but not as a workforce but as a control and final part of the process.

The industrial production sector has been radically changing following the integration of the virtual world of Information Technology into machines and the use of the Internet. Collaboration between operators and machines, speed of data exchange in real time, artificial intelligence, digitalization and flexibility of production processes are the elements that define the change we are facing. Tekna Automation and Control is able to transform these elements into an added value for its customers by providing fully automated production lines designed according to the most modern innovation and integration criteria, compliant with Industry 4.0 criteria.

The attention to the problem of waste disposal and their recycling has led many manufacturers to invest in the design of automatic machines for waste management. Tekna Automation and Control has realized the automation of machines and lines for the treatment of waste, starting from the compacting presses up to the complete waste sorting lines, whether they come from differentiated collection or not.

Environmental protection can be achieved thanks to efficient energy measures and energy production from renewable sources, photovoltaic, wind and biomass. Tekna Automation and Control is able to analyze customers’ energy needs and provide optimized solutions to reduce energy costs, using modern technologies for saving and producing energy from renewable sources.

Vision Tire System 3D ® is a family of machines designed and manufactured by Tekna Automazione e Controllo which scan the tire and, using laser profilametry, create the three-dimensional model of the tyre. Sophisticated software algorithms perform the detection, classification and measurement of defects present on the surfaces of the tire, and analyze the writings and symbols imprinted on the tire, to verify their compliance with the relevant production directives.

System Integrator or guarantee in the application and integration of different equipment in an automation system. Tekna Automation and Control uses PLCs, drives, inverters, brushless, axis controls from primary houses (Siemens, ABB, Rockwell, Shneider, Omron, Control Techniques, Lenze) in its automatic systems to satisfy the supply references of its customers.

In case of production lines downtime, technical support and prompt intervention are essential to ensure continuity of production. Teleservice is the innovative method of technical support operated remotely with the remote intervention of sector specialists. The automatic lines supplied by Tekna are designed to be connected remotely, via internet or direct connection and the software developed by Tekna, in addition to carrying out the automation of the lines, guarantee the interaction of the specialist with the control system and diagnosis. The specialist technician connects to the system, supervises it and guides the user step by step in order to solve the problem.

NEWS & EVENTS

Our interview for Rockwell at the Rockwell Automation Fair in Boston (USA)

During the ROCKWELL AUTOMATION FAIR event held in BOSTON we were interviewed by Mr Stan Miller, EMEA PUBLIC & ANALYS

MECSPE Bari 2023

We are pleased to have participated in MECSPE Bari, from November 23 to 25, 2023, at the Nuova Fiera del Levante. On thi

Logo